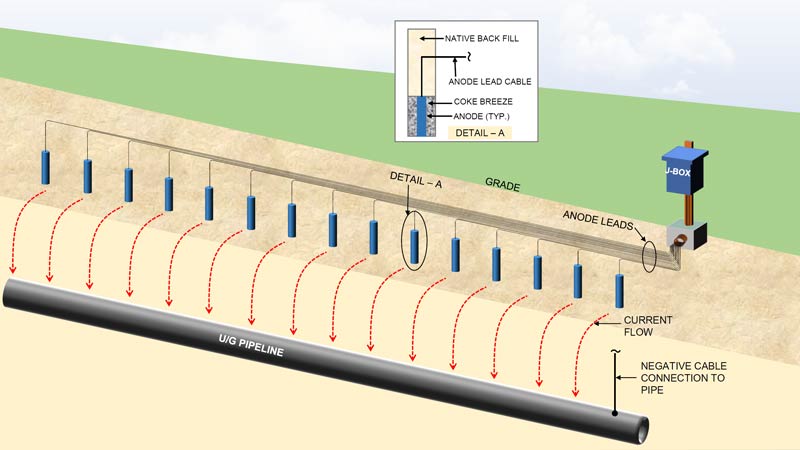

The remaining space is then filled with carbonaceous material. Another 4 designs with anode rods arranged as 26 28 29 36 are calculated respectively.

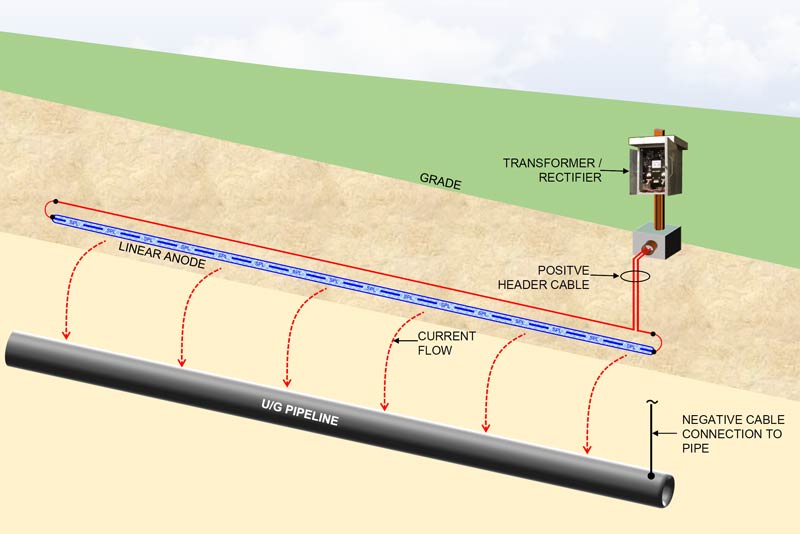

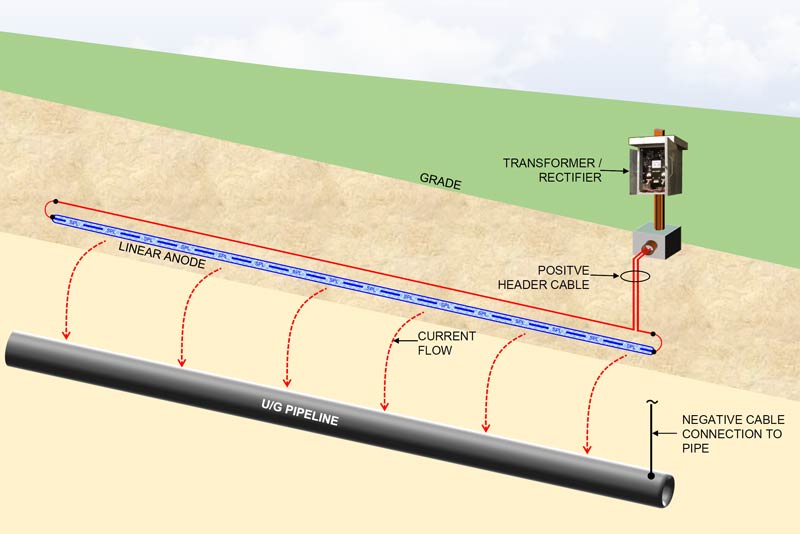

Shallow Horizontal Anode Bed Design With Linear Anodes Matcor Inc

A new CP ground-bed design compared with traditional design 27 14 anode rods dispersed in two parallel groups are calculated firstly.

. Search for jobs related to Cathodic protection ground bed design or hire on the worlds largest freelancing marketplace with 20m jobs. A basic design incorporates the use of a steel casing to prevent the collapse of the drilled hole. A cathodic protection program study indicated that conventional ground bed designs have three major disadvantages.

The results show that this design can not meet the grounding resistance requirement. Log in Register. The sacrificial metal then corrodes instead of the protected metal.

Once the groundbed becomes operative the steel casing will be consumed. This article reviews 3 steel pipe corrosion protection methods utilizing cathodic protection. The application of a groundbed serves the purpose of covering cathodic protection.

Cathodic Protection Provide a level of cathodic protection for the entire length of the underground structure. Deep anode ground bed systems have been utilized for decades to distribute cathodic protection current to protect pipelines storage tank bottoms well casings and other buried structures. The different anode 2 Sacrificial anode cathodic protection SACP ground bed configurations that are generally installed may Sacrificial anode cathodic protection sacrifices one require more than one design to fully evaluate the efficacy metal referred to as the anode in order to protect a given and cost effectiveness of a design.

I Abstract Iraq has a huge network of pipelines. A cathodic protection program study indicated that conventional ground bed designs have three major disadvantages. The cathodic protection system has been designed to protect the underground pipe 11 Codes and Standards All the design and installation for cathodic protection system shall be in accordance with the.

Several anodes attached together with a rope are placed inside the casing. A more flexible grounding resistance calculation method based on. The positive ground bed system consists of a remote horizontal anode system.

Another 4 designs with anode rods arranged as 26 28 29 36 are calculated respectively. Corrosion is usually defined as. Cathodic protection when applied properly is an effective means to prevent corrosion of underground plant piping.

Design Cathodic Protection Ground-Bed Arrangement with Finite Element Analysis Method. The conventional rectifier-ground bed system involves burying numerous non-sacrificial anodes about 100 ft from the well head and some 10- to 20-ft deep. In Chemical Engineering 2010 Jumada Al Akhirah 1434 March 2013.

Electrical Isolation Insulating devices must be installed on the steel pipe so as to facilitate electrical isolation. Cathodic protection system the design of anode ground bed plays very important role since the current distribution and pipe potential will be affected by anode position with respect to the. As compared with traditional grounding resistance.

Cathodic Protection Design for Buried Steel Pipes A Thesis Submitted to the College of Engineering of Alnahrain University in Partial Fulfillment of the Requirements for the Degree of Master of Science in Chemical Engineering by Shahad Fadhil Abed BSc. Poor current distribution occurs along the casing string. Cathodic Protection is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell.

Design Cathodic Protection Ground-Bed Arrangement with Finite Element Analysis Method. Resistance of Vertical Anode to Earth. A new CP ground-bed design compared with traditional design 27 14 anode rods dispersed in two parallel groups are calculated firstly.

Poor current distribution occurs along the casing string. It is a vital component of the grounding system. Its free to sign up and bid on jobs.

The NACE Standard RP-02-85 states that a minimum negative cathodic voltage shift of 300mV produced by the application of protective current should provide CP to iron and steels. A simple method of protection connects the metal to be protected to a more easily corroded sacrificial metal to act as the anode. The results show that this design can not meet the grounding resistance requirement.

Design Cathodic Protection Ground-Bed Arrangement with Finite Element Analysis Method A more flexible grounding resistance calculation method based on finite element analysis FEA method is suggested which is especially suitable for optimization cathodic protection CP ground-bed arrangement. This criteria does not apply to structures in. To obtain minimum no.

The voltage shift is measured between structure surface and a stable reference electrode contacting the electrolyte. In terms of cathodic protection this groundbed refers to the anodes arrangement in water or ground which provides a way for protective currents out of anodes into an electrolyte. 4 rows For planning and design purposes it is often possible to rely on.

For many underground applications such as pipelines cathodic protection system design is relatively straightforward. Of anodes in each GB three cases shall be calculated and maximum of those shall be selected. Cathodic protection levels must be controlled so as not to damage coatings.

Finally the design 2. The design of GB shall be for maximum output current and for a 20 years period.

Cathodic Protection Systems And The Nec Ec M

Schematic Design Of The Impressed Cathodic Protection Download Scientific Diagram

Cathodic Protection Systems And The Nec Ec M

Shallow Horizontal Anode Bed Design With Linear Anodes Matcor Inc

0 comments

Post a Comment