20100 m diameter spheres for uidized-bed reactors 0307 cm diameter spheres for xed-bed reactors 0313 cm diameter cylinders with a length-to-diameter ratio of 34 up to 25 cm diameter hollow cylinders or rings. The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix which in turn is governed by the shape dimensions and the loading of the.

Processes Free Full Text Thermal Assessment Of A Micro Fibrous Fischer Tropsch Fixed Bed Reactor Using Computational Fluid Dynamics Html

Varies with operating condition and reaction mixture.

. Table 71 lists some of the important commercial catalysts and their uses 7. The structure of the heat-exchanger type reformer including baffles tubes and a shell is presented in Figure 1. The design of Chemical Reactors is based on a few.

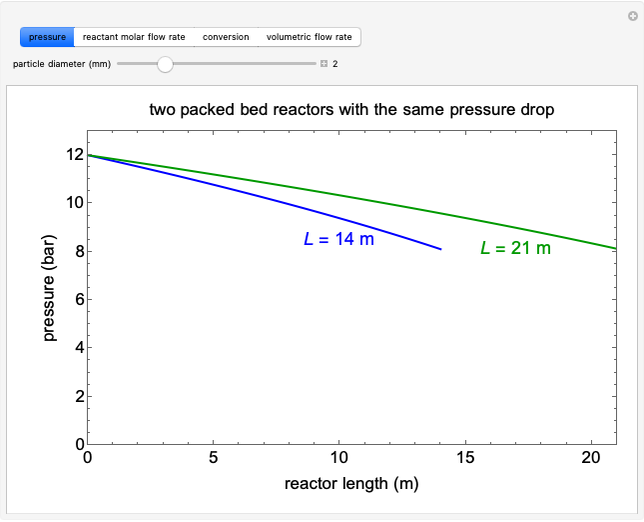

Where M molar flow rate dV is the incremental volume and is the rate of reaction per unit volume. Can be used to calculate pressure drop through bed sections packed with PROX-SVERS inert catalyst support balls. Packed Bed Data Select Particle Shape Particle Sphericity ΦS.

The Ergun Equation can be written as follows. To reactor length leaving us with the following parameters to be evaluated as a function of reactor length the fluid properties. P φμ φ.

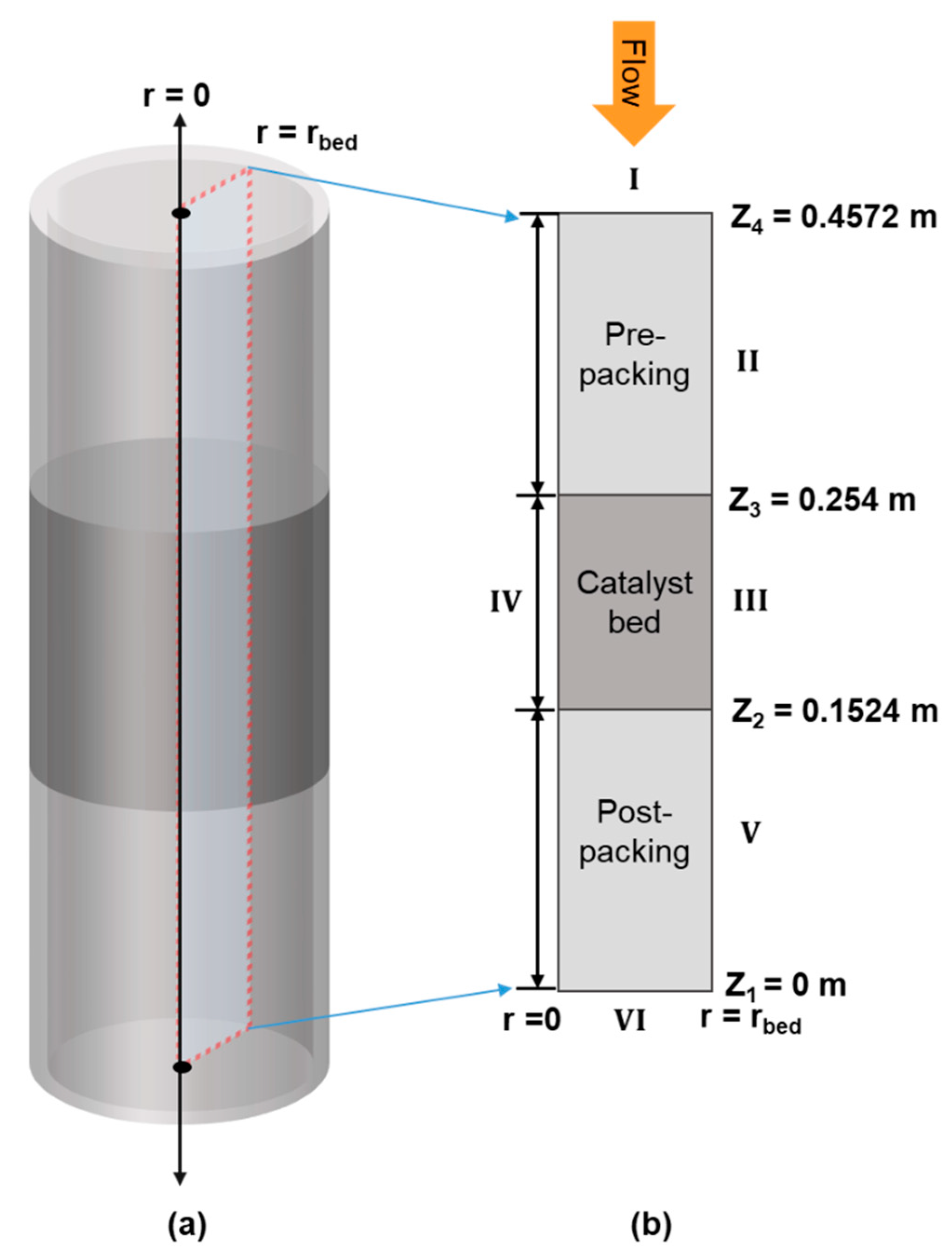

The conservation equations may be written for the steady state and a single reaction carried out in a cylindrical tube. Designers ensure that the reaction proceeds with the highest efficiency. 2 Flooded-Bed Reactor upward cocurrent two-phase.

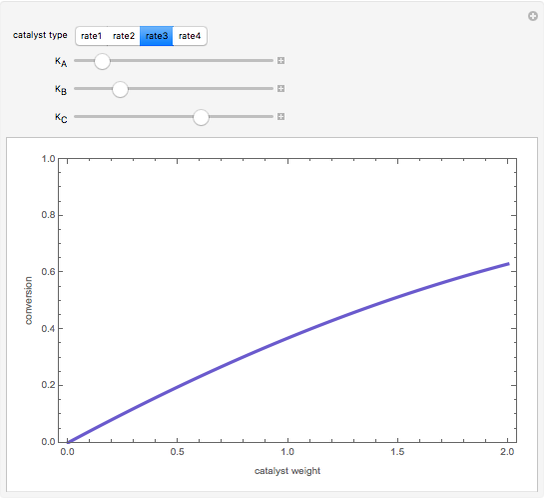

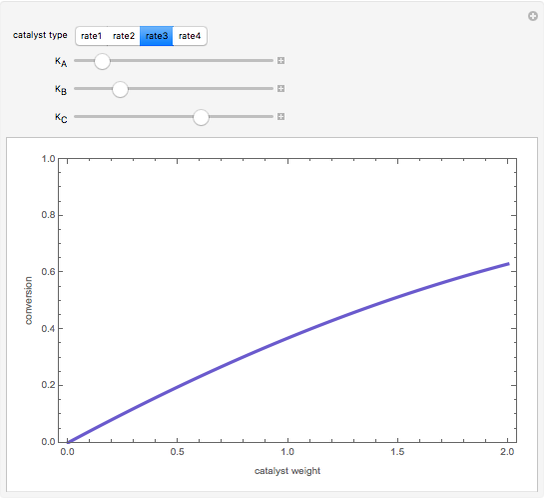

Reactor can handle large amounts of feed 1Good mixing 2. 1 Calculate Catalyst wight -W using mole balance equation dxdw -rAFAo 2 Calculate Reactor volume or Bed Volume VR with formulaW VR 1-фρc. Part of the reactor bed Figure4 Packed bed Reactors Kinds of Phases Present Usage Advantages Disadvantages 1.

Therefore the void volume is 149 ml or ε 149249 060. 175 1501 1 3. 75 Where P pressure drop lbin2 or psi L depth of the packed bed ft.

Dc u sÇBTA1 Us9fC P-AH PBr A- 4 Γ -T w2 with initial condition. The basic concepts of these reactors are shown in Figure 12. The reactor shell is usually surrounded by thermal insulation materials to avoid any significant amount of heat loss.

Significantly in the three-stage reactor the areas where the temperature of the inner tube is lower than that of the packed bed are minimized. G g D D G dz dP c p. 1 Trickle-Bed Reactor downward cocurrent two-phase flow Download our Trickle-bed simulator tbsimulzip and the updated version tbsimul_updatezip to simulate mass transfer pressure drop liquid holdup flow regime transition and wetting efficiency in trickle-flow.

Estimates packed bed pressure drop based on Ergun equation along with minimum fluidization and maximum superficial velocity. HCCOOHCOCO CHEMICAL REACTIONS AND DESIGN OF CHEMICAL REACTORS 5 a Tubular reactor plug flow b Tank reactor mixed flow. Equation for PFR is given by.

The general rules governing catalysts loading are i they should have a free fall distance of less than 05 m and ii the pellets must be distributed evenly as the bed is gradually filled. Viscosity μ and density ρ the operating parameter Fixed for a given packed bed. Atζ 0c c Q Τ T 0 In most cases the pressure drop in the reactor is relatively small so.

Chemical Reaction Engineering CRE deals with the design of Chemical Reactors to produce chemicals. Gas-Liquid Solid phase 1Heterogeneous reaction 2. G ρV mass velocity lbhr-ft2.

Temperature is relatively uniform throughout 3. All materials hav the same residence time τ and experience the same temperature and concentration profiles along the reactor. Chemical engineers design reactors to maximize net present value for the given reaction.

The reformer for MSR in this study is a multi-tubular packed-bed reformer. Chemical Reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of reactor. In this thesis predictions by the recently proposed wave models and the SDM have been compared for several industrial processes in order to indicate the range of applicability of the.

Experiments show that one 249 column can be packed with 081 grams of activated carbon so the volume occupied by the material is 1 mL. Also a conceptual part. Catalyst is charged into a fixed -bed reactor.

Tubes packed with CuZnOAl 2O. The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix which in turn is governed by the shape dimensions and the loading of the constituent particles. Figure4 Packed bed Reactors Type of Reactor Paced bed Reactor fixed-bedPBR is essentially a tubular reactor that is packed with solid catalyst particles.

Packed bed model equations has been studied and a robust and efficient software package for packed bed reactor modeling has been developed. For batch reactors conversion is a function of time whereas for flow reactors at steady state it is a functionofvolume 222 CSTRDesignEquation Using the expression for the volume of a given CSTR derived earlier we can eliminate F A by using theconversionofF A0 suchthatthedesignequationis V F A0X r A 5. Satisfactory results are obtained for both gas and liquid systems.

Comparing the one-stage reactor with the other reactors the proposed multistage reactors show fewer temperature differences between the inner tube and packed bed as shown in Fig. In industrial practice particles of desired size and shape are dumped randomly into a container to form a packed bed. The calculations assume the density of activated carbon and the liquid fuel are about equal at 800 kgm3 or 08 gmL.

1000 Particle Density ρp kgm³ Gas Data Gas Viscosity μf cP Packed Column Packed Bed Length L m Porosity Porosity at Minimum Fluidization εmf.

Packed Bed Reactor Design For A Gas Phase Catalytic Reaction Wolfram Demonstrations Project

Pressure Drop In A Packed Bed Reactor Pbr Using The Ergun Equation Wolfram Demonstrations Project

Pressure Drop In A Packed Bed Reactor Youtube

How To Find Volume Of Adiabatic Fixed Bed Reactor

0 comments

Post a Comment